Itsumi Manufacturing started its operation as R & D company of a press machine in 1951 and we are producing laundry equipment destined not only for Japan but also for the world market based on the total technology dealing with various finishers, driers and washers.

Itsumi is a leading company of a laundry equipment based on reliable technology.

We hereby would like to introduce Itsumi Manufacturing's product lineup such as a business use washer, various finishers and a drier.

-

2024.06.02

CB-100ST/140ST Steam and Dry box

Steam Box gets refined with a vibration feature.It employs an advanced controller with touch-panel, elaborately adjustable as per degrees of finishing and drying, available to diversified garments.Two models line up and meet various power supply requirements, out of one CB-100ST for 10 clothes and the other CB-140ST for 14 clothes.(→CB-100ST)(→CB-140ST) -

2023.05.24

ASEAN regional distributor

Added Leong Yew Engineering PTE, Ltd. as a member of Related Companies in charge of ASEAN regional distributor. -

2021.01.20

SP-700/500/300-EE / Laundry Utility Press

Launched Utility Press machine "SP-700EE, SP-500EE/ES, and SP-700EE/ES"which are fully remodeled.Utility Press with electricity driven and electric heater, used regularlyamong many Japanese users for a long time, were put on the world market withgetting environment performance refined and with features and design gettinginnovated. -

2017.04.01

GF-750AS-E / Multi former

GF-750AS was innovated to reflect users' desire and added to Multi Formerseries used for multiple purposes and it was launched as a new product.New GF-750AS is furnished with some new features and is applicable to notonly dry-finishing but also wet-cleaning. In terms of productivity, GF-750AScan contribute to improve that with swift and reliable finishing qualitytogether with getting its operating range broadening. -

2015.09.09

Single Buck Body Press/ BT-150-J

Single Buck Body Press/ BT-150-J was newly released on the market.

This product was added to "Single Buck Body Press" series that can give the finishing to both body and sleeve of a shirt simultaneously

It achieved meeting various designs and the quality finishing by improving vacuum capacity in addition to taking over angle adjustment function of the back stroke and the arm from the base model, BT-70-J.

(→For further information on BT-150-J, click here) -

2014.10.07

Single Body Press/ BT-70-J Saver

Single Body Press/ BT-70-J Saver, a shirt finisher was put on sale.

This product achieved reduction in finishing process time and long life deriving from inheriting and refining an advantage of BT-50-J popular for high cost performance.

(→For further information on BT-70-J Saver, click here)

-

2013.12.24

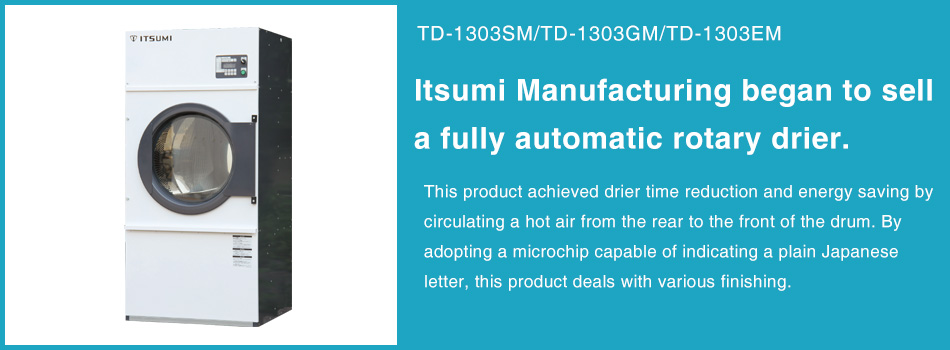

Full Automatic Rotary Drier TD-1303SM (steam), G (gas) and E (electricity)

Itsumi Manufacturing began selling Full Automatic Rotary Drier TD-1303SM (steam), G (gas) and E (electricity) on December 3, 2013.

This product achieved reduction in drying process time and energy saving by circulating a hot air from the rear to the front of the drum. By adopting a microchip capable of indicating a plain Japanese letter, this product deals with various finishing. -

2013.11.22

Fashion Pants Topper TO-550AS

Itsumi Manufacturing began selling new Fashion Pants Topper TO-550AS on November 4, 2013.

This product achieved high efficiency and quality of finishing by means of an automatic tuck equipment with a new function.

Accordingly TO-350AS will be supplied on build-to-order manufacturing basis. -

2013.06.27

Information on our homepage renewal

Thank you very much for your attention to Itsumi Manufacturing.

We are hereby pleased to inform our homepage renewal.

Please keep paying attention to our homepage as before, as we will make an effort in enhancing its contents. -

2012.10.03

New general catalog

New general catalog including Itsumi Manufacturing's steam box was provided

→ In case of downloading the catalog, click here.